Kudos to Dale!

Here is an article about Dale our founder in the latest woodworker institute. Here is a link to the site: https://www.woodworkersinstitute.com

Dale Guilford Woodturning Article

Here is an article about Dale our founder in the latest woodworker institute. Here is a link to the site: https://www.woodworkersinstitute.com

Dale Guilford Woodturning Article

Every hobby, sport and past time has it’s share of debates which help drive competition and innovation in that specific arena which in turn gives it life. Luthiers argue over whether a Taylor or Martin may sound better, but at the end of the day a Taylor’s neck is not engineered for a long life, but a temperamental one. This fuels the race to build a better mouse trap…in this example a guitar. Anyone rebuilding a 67′ GTO is going to have to face a lot of opinions on which shifter and intake perform better. The examples here are endless. One of the most polarizing debates amongst woodturners on lathe tools today is carbide vs. wood lathe chisels. Assuming some newcomers may reading this, I will briefly outline: Carbide inserts or known as carbide tips, carbide cutters, etc. are the interchangeable inserts that go in the end of a wood turning tool/ handle via a screw. They have a factory razor sharp edge and can be flipped for different angles and longer use . Wood turning chisels or wood lathe chisels are handles with a piece of steel with an edge like a knife. Like a knife you need to sharpen them to keep them sharp. Instead of creating a con and pro list, I will just briefly outline the benefit, advantage, and cons of each tool. Clearly we endorse Carbide here, however you will receive an honest and fair assessment. I can’t cover every angle of this argument but I will start with the following, and publish more down the road on this ongoing debate.

First off, many of wood turners use both carbide and chisels. There are good and varied reasons, but lets start with the fact that wood lathe chisels are the oldest tool used for the job and continues in an old school camp of turners. Carbide inserts are a reasonably new technology, so wood turners up on the latest and greatest will naturally gravitate to carbide for that reason to start. Carbide is much easier and there is less of a learning curve. However, sharpening your chisel, if you’re skilled and experienced will save you insert bucks in the long run. However, you have to look at the nominal cost of an insert and ask yourself if the time saving benefit of not sharpening is right for you. It’s the difference between sharpening your kitchen knife, or pulling out a new one every-time you need it sharpened…but without throwing the knife handle away. Most importantly, when hollowing forms carbide inserts are scrapers, and traditional gouges are slicers. However the cup cutters like the AA Carbide’s cup cutters and Hoggers are more of slicers. Slicing will always give you that immediate satisfaction of a refined surface where gougers are more chiseled and rough. The immediate satisfaction is popular for nubies.

One popular choice for even the old school hold outs are using gougers with carbide inserts for hollowing. Sharpness and angle is very critical to a good hollow and makes short work of it. This is why you find both camps using carbide for hollowing forms.

At the end of the day many woodturning professionals and hobbyists would say choosing carbide inserts or chisels boils down to tradition vs. the latest technology. A lot of wood turners use and make their own tools and handles. So are you a purist or traditionalist? I wish I could write more on it, but its really that simple. So what are the best woodturning tools for the job? As an authority on carbide inserts, we would ask whether you’d chop a tree down with a chainsaw or axe?

Here’s a lofty one for those Philosophical turners:)

Woodturning is considered by most turners to be an art form, and a cathartic one at that. It’s a fantastic way to kill time (before or after retirement), and excellent medium for self expression. Like all artistic mediums technology has impacted woodturning. On one extreme end of the scale, CNC machines and computers plot designs to lathes and cutters in no time flat for consumers. However, this technology cannot match or take away from the true artist essence of a hand-crafted bowl or vessel. So then, why do we turn wood if it can be done so easily by a machine? and for whom are we turning??

Before we go any further, I am going to spoil it and answer the question this very blog title begs. In a nutshell, technologies impact on woodturning has been on safety. We’ll come back to the side topic of “purpose” in a moment for fun.

Centres, tapers, belts systems, swivels, and user controls (interfaces) have all evolved for our safety, as well as ease. Woodturning can still be dangerous, but we are less likely to hurt ourselves turning wood than we were 2oo years ago. Tools are also better. Handles are more ergonomic and promote optimal use and muscle memory, and carbide inserts are machine sharper and designed to do a more efficient job than ever before. Hollowing systems are also better engineered to get the job done more efficiently, faster, easier and yes, safer.

So, coming back to he question and purpose of wood-turning, brings out my luddite cynicism, and reminds me of other cautionary tales such as the “ballad of John Henry” https://www.youtube.com/watch?v=OF-3t8Id6mA . Ned Ludd of course (historically debated) destroyed the printing press in fear of his economic security. Same reason John Henry took on the steam driver. I think many artists, craftsmen, and hobbyists contemplate this today, as they grapple to use technology as a tool and even as a medium. Do they wonder how far technology will go? Should we care as craftsmen or artists? Many art forms and professions become antiquated as technology presses on. You can’t stop progress. However, my purpose for turning is as personal as the next woodturner. We turn for ourselves, art admirers, and for people who just appreciate beautiful and useful things made by another human being. the rewards can be fun, lucrative, and relaxing all at once. Now, it is all of that and safe.

At the end of the day It’s not craftsmanship, thats coming from a computer.

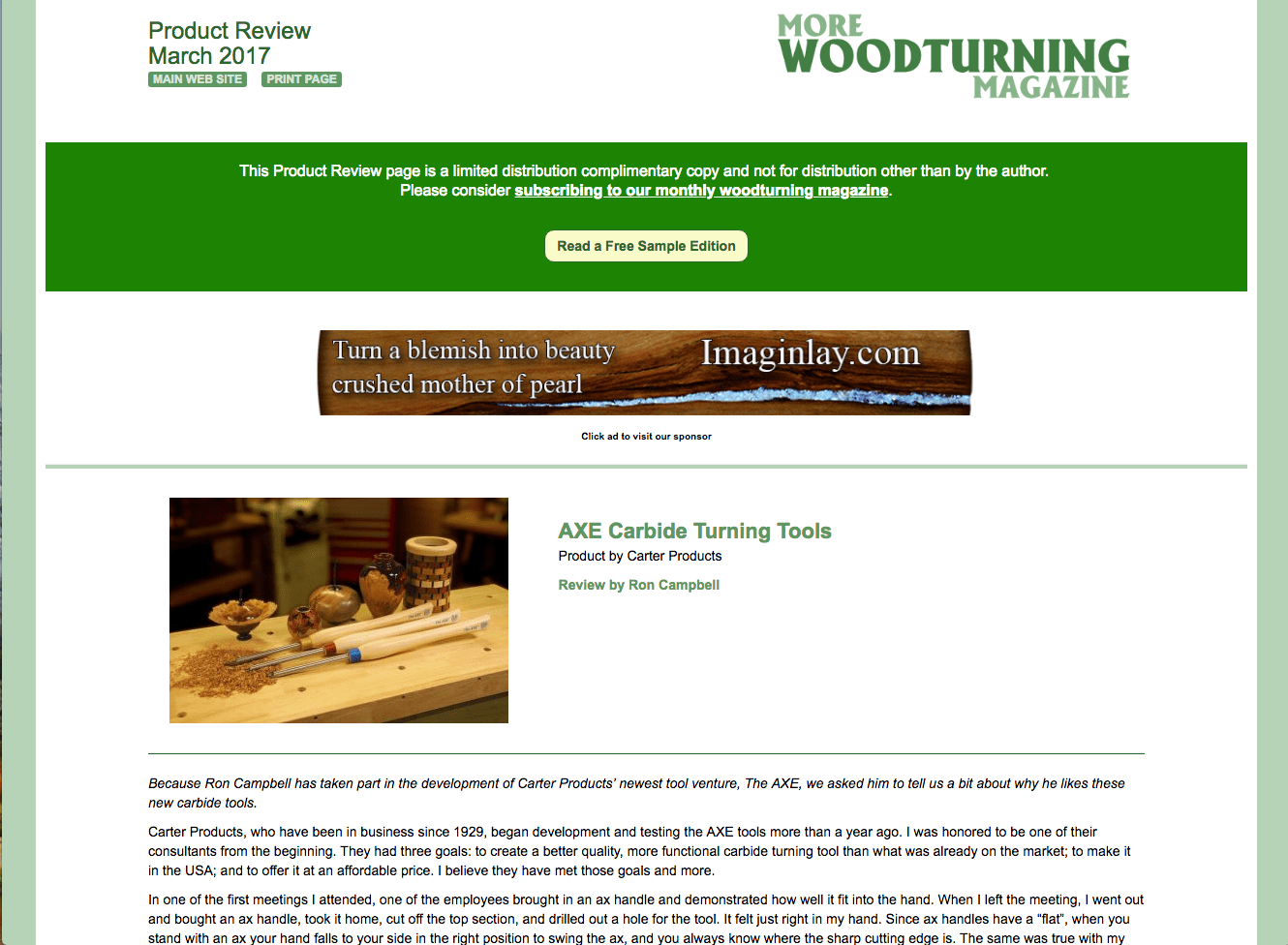

Read the entire article here!

https://www.morewoodturningmagazine.com/reviews.php?reviewsid=23&access=c84eac04dd8e

If you own one of the Sorby Turn Master tools, or are considering purchasing one, this video will show a quick change you can make so that a greater variety of carbide insert cutter styles can be used.

The change is adding a slight countersink to the top of the mounting hole on the tool head. With this change many more cutter styles can be used on the TurnMaster.

The 15mm round, square, radius and large diamond insert cutters available from AZ Carbide can now be mounted on the TurnMaster.